Application of Carbon Fiber in the Auto Repair Industry:

Innovation from Repair to Upgrade

As the automotive industry's demand for lightweight, high-strength materials continues to grow, carbon fiber, with its unique properties,

is gradually moving from a "high-end option" to popularization in the auto repair industry.

It not only provides better solutions for vehicle repair but also opens up new paths for performance upgrades.

I. Body Structure Repair: Precise Restoration and Enhancement

In traditional auto repair, the repair of collision deformation of metal body parts (such as frames and longitudinal beams)

often relies on processes like hammering and welding,

which are time-consuming and may cause a decline in metal performance due to high temperature or external force.

However, carbon fiber composites show significant advantages in repair:

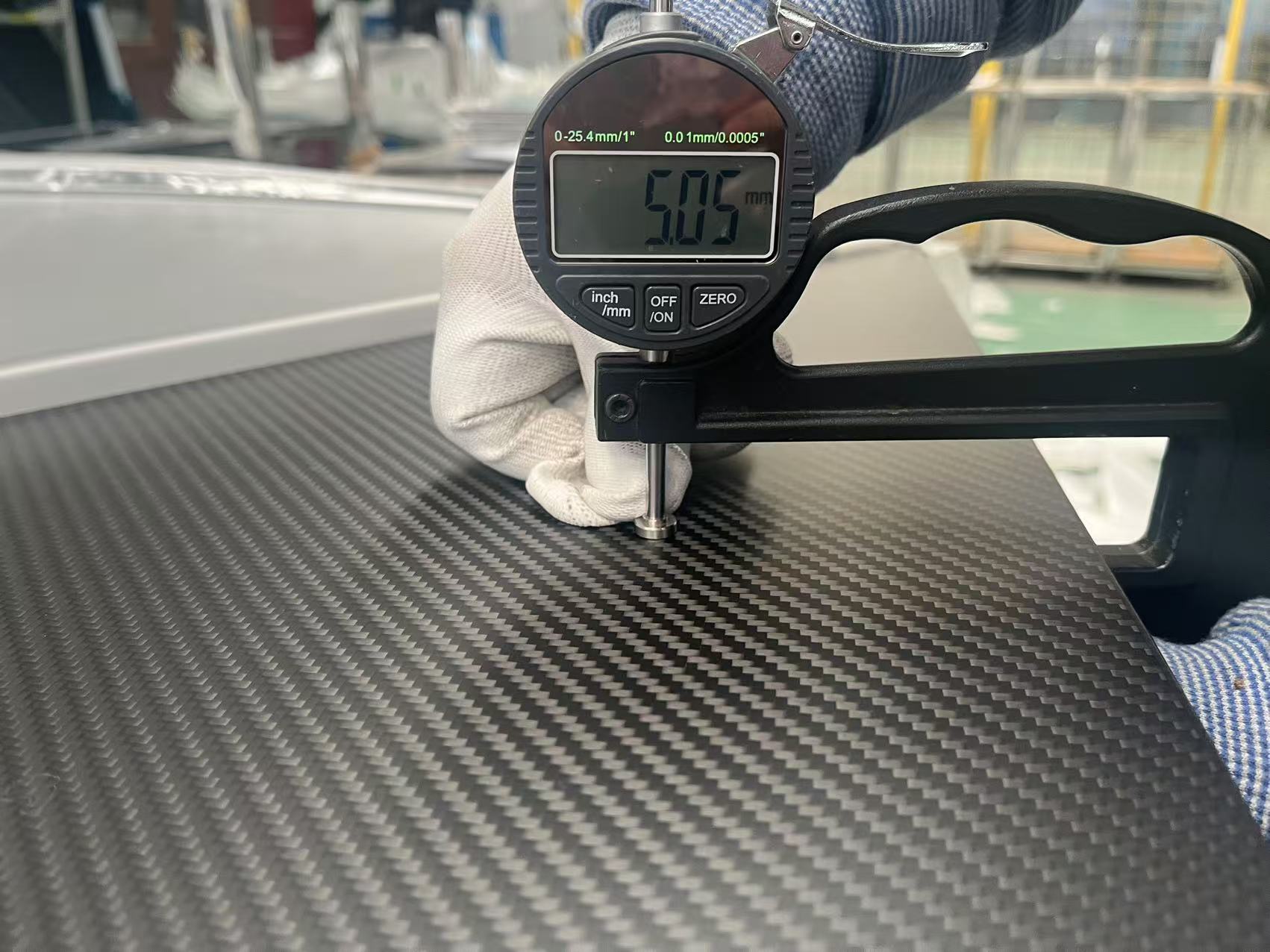

• For slightly deformed carbon fiber parts (such as the engine hoods and spoilers of some high-end models),

they can be repaired through processes like special resin filling and curing,

avoiding overall replacement and greatly reducing maintenance costs.

• For local damage to metal bodies, carbon fiber cloth bonding and reinforcement technology can be adopted.

By cutting carbon fiber cloth of appropriate size and pasting it on the damaged part with epoxy resin, after curing,

it can form an overall stress with the original structure, with strength even exceeding that of the original metal parts,

while reducing the weight after repair.

• For the reinforcement of metal structures of old vehicles (such as rusted chassis crossbeams),

the corrosion resistance and fatigue resistance of carbon fiber composites can extend the service life of components

and reduce the probability of secondary maintenance.

II. Performance Upgrade: Lightweight and Handling Optimization

In the field of automobile modification and performance repair,

carbon fiber has become a core material to improve the dynamic performance of vehicles:

• Component Replacement: Replacing traditional metal components (such as drive shafts and suspension arms)

with carbon fiber products can significantly reduce unsprung mass, improving vehicle acceleration, braking, and handling response.

For example, carbon fiber drive shafts weigh only 1/3 of steel ones but can withstand higher torque, reducing power transmission loss.

• Aerodynamic Optimization: During auto repair, installing carbon fiber front lips, side skirts, diffusers,

and other components can not only repair damage to original parts but also optimize body airflow, reduce wind resistance,

and improve high-speed driving stability.

These components are not only lightweight but also can be customized to fit different models.

III. Repair of Special Components: Meeting the Needs of High-End and New Energy Vehicles

With the popularization of new energy vehicles and high-end models,

the application of carbon fiber components has become more widespread,

and their maintenance needs have increased accordingly:

• If the battery shell of a new energy vehicle is made of carbon fiber composites,

minor damage can be repaired through resin repair technology to restore sealing and structural strength,

avoiding the high cost of overall replacement of the battery shell.

• Some components of supercars or performance cars, such as carbon fiber chassis guards and brake cooling ducts,

can be accurately restored to their aerodynamic performance and protective functions through professional

carbon fiber repair processes after damage, and the weight after repair is almost the same as the original components.

IV. Challenges and Future

Although carbon fiber has obvious advantages in auto repair, its application still faces some limitations:

professional repair requires mastering special processes such as carbon fiber molding and resin curing,

which have high skill requirements for maintenance personnel; the initial equipment and material costs are relatively high,

and it is currently more used in mid-to-high-end models.

However, with the popularization of technology and cost reduction,

carbon fiber repair technology is gradually penetrating into mainstream auto repair shops.

In the future, with the further popularization of carbon fiber in automobile manufacturing,

its application in the auto repair industry will be more extensive - from daily minor scratch repair to in-depth performance upgrading,

carbon fiber will become an important force promoting the development of

the auto repair industry towards "precision, lightweight, and high efficiency".